Table of Contents

As an advanced form of welding, plasma cutting has been popular among welders since the 1960s as it allows for cleaner and more accurate cuts. However, since plasma cutting involves working with electrically ionized and superhot gas, your whole body should be protected when you are cutting through metal with a powerful jet of plasma. Most importantly, you must safeguard your eyes with special protective gear so that you can work and see clearly at the same time.

If you need to deal with plasma cutting regularly and are wondering what to get to have the best protection for your eye, this article is for you. Here, we will introduce you to a range of eye protection gear and discuss how to pick the best one for yourself. But before that, let’s take a look at the reasons why we are prioritizing eye protection in this post.

Why You Need Eye Protection For Plasma Cutting?

The most important reason to use eye protection for plasma cutting is the flying debris and the emission of intense radiation.

Like in any welding operation, the possible hazards from flying metal particles, sparks, and other debris necessitate the use of proper eye protection. During plasma-cutting operations, such flying bits can cause serious injuries to your eyes and surrounding area if you are not using protective measures.

Moreover, a plasma cutter generates an electric arc. With a plasma stream temperature of up to 36,000 °F or 20,000 °C, this electric arc is responsible for emitting electromagnetic radiation- ranging from infrared to ultraviolet rays. Looking directly at these bright blue lights can cause serious damage to your retinas. These rays can be so intense and damaging that you may end up permanently blind.

Eye Protection Gear For Plasma Cutting

It should be pretty obvious by now that we should be extra careful about our eyes when handling a plasma cutter. In this case, a basic pair of safety glasses will not be enough. Hence, there is special eye protection gear that is developed particularly for plasma cutting.

Plasma Cutting Goggles

For an average plasma-cutting task, a pair of plasma-cutting, welding, or torch goggles will do as long as they have a filter shade value of at least 5. The shade number indicates how much light radiation your goggles are allowing to pass through its filter lens. As this number goes up, less light radiation goes through your goggles, and your view becomes darker.

Some plasma-cutting goggles have features to enclose the surrounding area of your eyes, whereas some have flip-up lenses of various shades so you can adjust the shade value by yourself. Using a pair of rectangular torch goggles is also a good option as they are equipped with flip-up shields and offer excellent visibility even when working with maximum temperature.

Plasma Cutting Lenses and Glasses

Plasma-cutting glasses are specially designed to tackle UV rays and intense radiation. They also protect your eyes from hot plasma. The darkness level or shade number of the glass should be determined based on the project and the type of metal you are working with.

Alternatively, for a low-intensity plasma-cutting task, safety glasses with yellow lenses are enough, as yellow lenses are very effective for blocking out blue light. However, we recommend getting a pair with a high shade value.

Plasma Cutting Helmets

It is impossible to wear a plasma-cutting helmet without feeling super cool. While radiating a Cyberpunk vibe, plasma-cutting helmets are excellent for protecting your entire head, including your face and eyes.

They are also available in a range of shade values, and you can pick the ideal one for your project. For example, a shade 5 helmet will suffice for plasma cutters of up to 40 amps. But if you need to comply with OSHA, then choose one with a minimum shade value of 8.

Face Shields

If you feel uncomfortable wearing safety glasses, enclosing goggles, or a heavy helmet, you can opt for face shields. They offer good protection for your face and eyes and are more comfortable than the previous options.

You can also pick one as per your desired shade value. However, we do not recommend using a face shield alone for heavier plasma-cutting jobs as they are not strong enough.

OTG Safety Glasses

If you wear prescription glasses, OTG safety glasses will be the most convenient for you. They come coated with IR and UV protection material and can easily fit over your regular glasses. Therefore, you can ensure precision in your plasma-cutting job.

However, OTG safety glasses with high shade value are usually unavailable. The American Welding Society and ANSI (American National Standards Institute) do not have any guidelines on these glasses’ minimum shade value either. Hence, you can use them only for short and low-current plasma-cutting operations.

Factors to Consider When Choosing Eye Protection for Plasma Cutting

When choosing the best eye protection measure for your plasma-cutting operations, it is crucial to be very meticulous in your search. Therefore, based on the types of projects you are handling and the following factors, make your choice.

Shade Specifications for Plasma Cutting

Operations like welding, torching, and plasma-cutting bear a broad range of risk factors. Therefore, OSHA (Occupational Safety and Health Administration) provides several eye-protection requirements that keep updating with technological advancement in this field. Among these, the most important measure is the shade number.

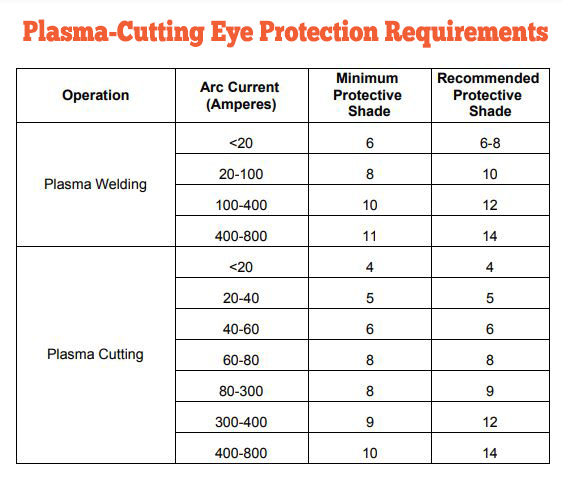

For plasma-cutting operations, the table below will help you match the shade value of your eye-protection gear with the arc current of your job.

Ultraviolet Light

The eye damage caused by ultraviolet light emission from welding operations is called “arc eye” or “welder flash”. Therefore, your eye-protection gear should be coated with UV protection materials and have a rating of at least U2. The higher the rating, the better protection you can expect. A rating of U6 indicates that the gear will block 99.9% of UV light emitted from a plasma cutter.

Auto-shading

Some eye-protection devices can automatically adjust their shading based on the cutter ampere. This auto-shading technology helps welders easily reach the optimum point between visibility and protection within a few seconds. However, such devices are expensive and require batteries. But the convenience and safety they offer are of the best value.

ANSI Z87 Safety Rating

ANSI also developed its own standards regarding eye protection- the ANSI Z87.1 standard. OSHA mandates all workers to wear safety glasses, face shields, or helmets that have the ANSI Z87.1 certification. Hence, while buying eye protection gear for plasma cutting, check for the ANSI Z87.1 rating.

Fit

It is crucial to ensure that your plasma-cutting eye protection device fits you properly. If it does not fit well, you will not be able to work comfortably at all. Your project will also suffer due to a lack of precision in cutting. Fortunately, most plasma-cutting eye protection devices are elastic or have features to optimize adjustability.

Final Thoughts

To conclude, it is imperative to prioritize getting the highest level of safety while choosing an eye-protection measure for your plasma-cutting operations. Based on the amperage output of arc current, the requirements of your project, and the type of metal you work on, choose the highest filter shade value. Check for all the necessary certifications and ratings as well. Get a high-quality device from a reputable manufacturer to ensure high durability, endurance, and performance.

Leave a Comment